The National Technical University of Athens (NTUA) was founded in 1836 and is Greece’s oldest and most prestigious technological institution, consistently contributing to scientific, technical, and economic development. With a strong emphasis on research, NTUA maintains a distinguished position among European universities, actively participating in numerous EU-funded and international projects.

The Unit of Process Control and Informatics (UPCI) is part of the School of Chemical Engineering at NTUA and has extensive experience in the areas of chemo, bio, nano, and pharma informatics. UPCI has participated in several FP7, H2020, and Horizon Europe projects, leading work packages related to modeling, analysis tools, and IT infrastructure development. Research at UPCI primarily focuses on automatic control systems, process modeling and optimization, artificial intelligence, and data analytics. By utilizing advanced machine learning and mathematical modeling techniques, UPCI is developing new methodologies, including:

- QSAR modeling for chemical hazard assessment using AI and read-across methods.

- Physiologically-Based Kinetic (PBK) modeling for evaluating chemical biodistribution and risk assessment.

- Deep learning-based image analysis tools for nanoscale material characterization.

- Optimization of production processes aligned with Life Cycle Assessment (LCA) principles.

- Process control systems for real-time manufacturing safety and efficiency.

- Multi-scale modeling for chemicals and materials.

- Large Language Models (LLMs) and generative learning approaches for novel chemical and material design.

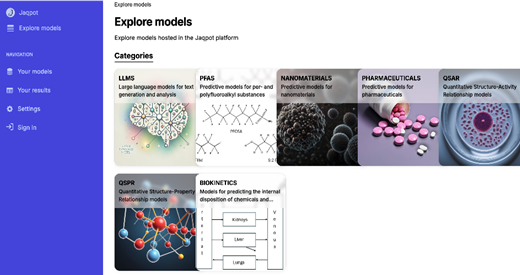

Through its Jaqpot cloud-based platform, UPCI ensures that state-of-the-art modeling tools are freely accessible to the research and regulatory community. The Jaqpot modelling platform (available http://www.jaqpot.org/), streamlines the development, deployment, hosting, and sharing of computational and machine learning models (including QSAR, PBK but also LLMs and generative learning models). The platform features a central graphical user interface for accessing the models, while Jaqpot APIs facilitate interoperability and connections between tools, and allow for seamless communication and linking with external applications.

NTUA’s Role in the CHIASMA Project

Within the CHIASMA project, NTUA-UPCI contributes to the development of in-silico NAMs. Our work focuses on developing QSAR and Physiologically-Based Kinetic (PBK) models to enhance predictive capabilities for regulatory evaluations. PBK models simulate the absorption, distribution, metabolism, and excretion (ADME) of chemicals and materials. They bridge in vitro findings with exposure scenarios and support reverse dosimetry for toxicological risk assessments. Additionally, QSAR models predict toxicological endpoints and assist in hazard identification for the CHIASMA demo cases. NTUA-UPCI also contributes to the development of a modular digital engine to implement Integrated Approaches to Testing and Assessment (IATAs), which streamlines the use of these in-silico tools. This makes the methodologies more accessible, scalable, and applicable to diverse stakeholders, ultimately promoting safer, more sustainable, and animal-free regulatory practices for chemicals and materials.

“As the demand for sustainable solutions continues to grow, the landscape of safety assessment is undergoing a transformative shift. CHIASMA is leading the charge in developing and evaluating novel animal-free methods for the regulatory evaluation of chemicals and materials. As a partner in this initiative, we are excited to contribute by supporting this transition through cutting-edge in-silico modelling. Our focus is on creating and implementing computational New Approach Methodologies (NAMs) for safety assessments. While challenges may arise, we are fully confident that, through our collaboration with CHIASMA partners, we will achieve remarkable progress that will reduce animal testing and will bring us closer to a safer, more sustainable future..”

[Haralambos Sarimveis (Professor of Chemical Engineering at NTUA)]